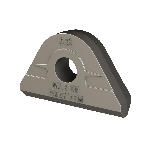

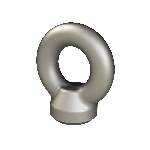

WELD-ON LIFT POINTS

Quality weld-on lift points for a wide range of anchoring and lifting

applications! Available in various materials, types, and capacities.

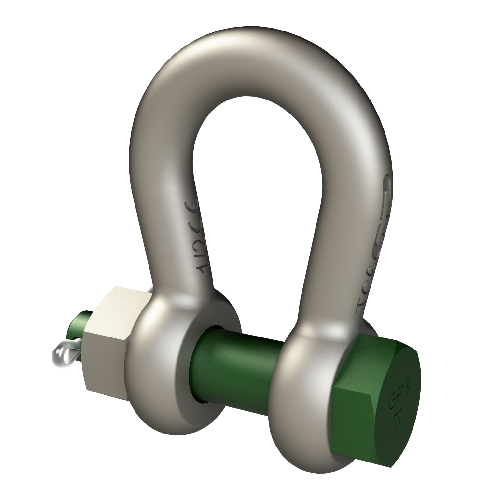

SAFETY PIN BOW SHACKLES

- Premium quality rigging equipment from GreenPin®

- Double safety (cotter pin and safety bolt)

- Galvenization assures long-term durability

- Suitable for both one-leg and multi-leg systems

- Conformed to wide range of certifications (e.g. DNV)

Our Products

ABOUT US

PadEye.com is your source for ASME BTH-1 compliant below-the-hook lifting products and equipment. From shackles and forged lift points to switchable magnets and specialty equipment, we've got you covered!

Our off-the-shelf, engineered, certified, forged pad eyes are a revolutionary alternative to custom fabricated lifting lugs. By stamping each pad eye with with all the vital information (including minimum weld deposit, welding qualification, max pull indicator, etc...), and certifying them to meet all ASME BTH-1 categories and classes, we've removed the guesswork and made a product that's too convenient not to have on hand!

Meet the Har-Bach Family of Companies

Fit Up Gear®

Innovative fitting tools for the fabrication of storage tanks, ships, barges, rigs, and countless other applications.

Har-Bach Positioning

Welding positioners, turning rolls, manipulators, chucks, slides, etc... for industrial automation applications.

Circle Welding Innovations

High quality nozzle welders and circle burners for pressure vessels, power piping, and sprinkler systems.

Pathfinder Seam Tracking

Triple laser, plug and play, optical seam tracking systems for advanced welding automation processes.

Fusion Technologies

Wear and corrosion resistent solutions, advanced welding equipment, process control, and material innovations.

Orbital Service

Cutting edge welding machines, open/closed tube welding heads, novel remote controls, and top-of-the-line accessories.

TESTIMONIALS

We chose Padeye.com for less weld time, lower cost, and space savings. Compared to your “CSA” padeye, our lifting lug has 8” more weld length which adds 30 minutes @ a labor rate of $105/hr and cost is about $15 higher for our lifting lug compared to the "CSA" padeye. In comparison to your “CSC” padeye, our lifting lug has approximately 15” more weld length which is 45 minutes additional weld time plus cost is about $40 higher.

A. Goodman, Designer

There has been a need for this in our industry for a long time and I'm excited to see this come together.

T. Mackey, Engineer

CONTACT US

Har-Bach Marketing, Inc.

218 W. Richey Road

Houston, TX 77090

Telephone: ( 281) 440-1725

FAX: (281) 440-1724

E-mail: sales@fitupgear.com

FOLLOW US

Please Click Submit Once